When shopping for a sleeping bag, you might notice the price can be quite high. This may lead you to wonder why such a simple product costs so much.

Sleeping bags are expensive because they use high-quality materials and advanced technology for better insulation and comfort.

These materials need to withstand harsh weather conditions while being lightweight and portable.

The design and craftsmanship involved can also add to the cost. So, when you see a high price tag, remember that it reflects the value and performance you get out of it.

Investing in a good sleeping bag can enhance your outdoor experience. Understanding what goes into their pricing helps in making a more informed decision about where to spend your money.

Material Costs and Quality

Sleeping bags often come with high price tags due to the cost of high-quality materials. These include premium insulation, durable fabrics, and advanced water-resistant features.

The video will be loaded from YouTube.com, a third party. If you play it, you accept their terms of service, and their use of cookies.

Premium Insulation Materials

High-end sleeping bags often use advanced insulation materials like down or synthetic fibers.

Down is lightweight and provides excellent warmth by trapping heat efficiently. It’s usually sourced from ducks or geese and undergoes a cleaning and processing stage that increases costs.

Synthetic insulation is often made from polyester fibers. It can be more affordable but may require special treatments to improve insulation quality. Differences in loft, warmth-to-weight ratios, and hydro-phobic treatments make these materials more expensive.

Durable and Lightweight Fabrics

The fabrics used in sleeping bags are designed to be both durable and lightweight. Popular choices include ripstop nylon and polyester, known for their durability and tear resistance.

Manufacturers often coat these fabrics with special materials to enhance durability, adding to the cost. The fabric must handle regular compressions and expansions without wearing out quickly.

Moreover, the lightweight nature of these fabrics makes it easier for you to carry the sleeping bag.

Water-Resistant and Breathable Technologies

Sleeping bags need to resist water while remaining breathable. This involves technologies like DWR (Durable Water Repellent) coatings.

These treatments let water bead up and roll off, preventing moisture from soaking in. It’s critical for keeping the bag dry in wet conditions.

Breathability is equally important to prevent the build-up of condensation inside the bag. Technologies such as Gore-Tex or other specialized membranes allow moisture from sweat to escape. These technologies require complex manufacturing processes, which can increase costs significantly.

Design and Ergonomics

Design and ergonomics play a big role in the cost of sleeping bags. Key factors include how well the bag fits the human body, its ability to adapt to various temperatures, and innovative features that enhance comfort and usability.

Rab’s expensive sleeping bags

Anatomical Considerations

Sleeping bags are crafted to fit your body comfortably. Designers consider body shapes and sleep positions.

Mummy bags are narrower at the feet and wider at the shoulders to save weight and retain warmth. Rectangular bags offer more room but are heavier.

Choosing a sleeping bag that aligns with your sleep style enhances comfort. Draft tubes prevent heat loss through zippers. Hood designs add warmth by enclosing the head.

Ergonomic designs often mean higher production costs, contributing to the price of the bag.

Temperature Ratings and Versatility

Sleeping bags come with temperature ratings to help you choose what suits your needs. These ratings show the lowest temperature at which the bag will keep you warm.

It’s important to consider your comfort level when picking a bag.

Versatile sleeping bags let you adjust for different weather conditions. They might have zippered quilts or layered designs for temperature control.

The materials used for insulation, like down or synthetic fill, affect warmth and cost. More adaptable bags can be more expensive due to their multifunctional components.

Specialized Features and Innovation

Modern sleeping bags often feature specialized technologies. Some have water-resistant finishes to handle damp environments. Others include built-in pillow pockets or sleeping pad sleeves to keep you comfortable and secure overnight.

For those keen on saving weight, ultralight materials are used, although these can boost the price significantly. Glow-in-the-dark zippers and anti-snag features improve user experience and convenience.

Investing in research and development for these features increases the cost, but they offer significant comfort enhancements.

Brand Reputation and Marketing

Brand reputation and marketing significantly affect the cost of sleeping bags. Companies with strong brand images and strategic marketing efforts often command higher product prices.

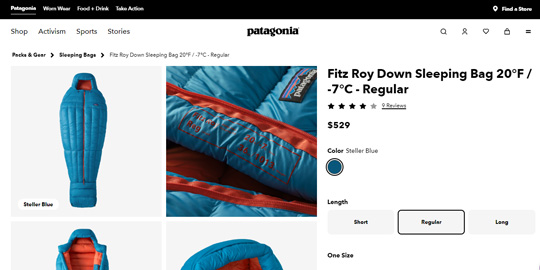

Patagonia sleeping bag

Brand Image and Positioning

Well-known brands often charge more. These companies spend a lot of money on advertising and creating a strong image.

Consumers trust brands that are seen as high-quality and reliable. This reputation allows them to set higher prices. When you buy from a well-known brand, you often pay for the name, not just the product.

This trust in quality and performance justifies a higher price.

Also, brands focus on positioning themselves in a specific market segment. Some aim for luxury markets, while others focus on budget-friendly options.

The ones targeting high-end consumers might use premium materials, adding to the cost.

Sponsorships and Endorsements

Sponsorships and endorsements also play a big role in pricing. Brands often pay athletes and celebrities to use their products publicly.

This type of marketing is costly but increases exposure and brand value. These costs are usually reflected in the product’s price.

Endorsements create excitement and draw attention to the brand. If a celebrity is using a specific sleeping bag, it might make others want to purchase it, too.

This increased demand can lead to higher prices due to the exclusive appeal.

Manufacturing and Labor Costs

The cost of making sleeping bags can be high due to ethical manufacturing practices and the expertise required in crafting them. These elements affect both pricing and quality.

Ethical Manufacturing Practices

Ethical manufacturing focuses on fair labor practices and environmental concerns. Many sleeping bag brands prioritize treating workers well, ensuring fair wages and safe working environments.

Producing goods under these conditions can increase costs. Factories may follow strict environmental guidelines to reduce pollution and waste, affecting their overall operating costs.

Consumers are often willing to pay more for products that align with their values and demonstrate corporate responsibility.

Brands that commit to these practices must balance ethical standards with the need to remain competitive in pricing.

Skilled Labor and Craftsmanship

Making a high-quality sleeping bag often requires skilled labor. Workers need training to combine materials like insulation and waterproof fabrics effectively.

Skilled craftsmanship ensures better product quality, durability, and performance.

Crafting sleeping bags involves techniques and precision to make sure they provide insulation, comfort, and durability. Investing in skilled labor can lead to higher prices but also results in better-performing sleeping bags.

Brands invest in training and maintaining skilled teams, which can be reflected in the price tag of the final product.

Distribution and Retail Margins

Sleeping bags can seem costly due to various factors. Distribution and retail margins play a significant role in the final price. Costs aren’t just about manufacturing but they include getting the product to stores and selling it for a profit.

These processes have their expenses, contributing to why you might pay more than you expect.

Transportation and Storage

Shipping sleeping bags from factories to stores involves logistics costs. This includes loading, transporting, and unloading items.

Companies must rent or own warehouses to store products until they reach stores. Fuel prices, shipping materials, and labor for handling add to the expenses.

Storage facilities need to be climate-controlled to maintain bag quality. Each of these processes requires money, adding to the price. The farther a product has to travel, the higher the logistics costs.

Instead of just being costs of fabric and fillers, transportation and storage push up the price as well.

Retail Markup and Profit Margins

Once sleeping bags arrive in stores, retailers set a price higher than what they paid. This is known as markup.

Markup covers operational costs like employee wages, building rent, and utilities. It also ensures shops make a profit.

Retailers often aim for specific profit margins, meaning they plan to make a certain amount of money on each sale. The markup usually includes the cost of any promotion or advertising.

So, when you see a price tag, it reflects not just the cost of goods, but the money needed to keep stores running.

Research and Development Costs

When you buy a sleeping bag, a lot of work has gone into making it just right. The research and development (R&D) stage is key in designing sleeping bags that keep you warm, dry, and comfy.

Materials are a big focus.

Experts study how different fabrics perform in varying conditions. They test for warmth, weight, and waterproof qualities, ensuring they pick the best materials for your needs.

Many designs don’t work out at first.

Engineers create prototypes, which they test again and again. They look for the best shapes and features to keep you cozy in various environments. This testing involves trials in labs and real-world conditions.

Sometimes, research includes working with new technologies. These are often more expensive but can improve how a sleeping bag performs.

Whether it’s creating heat-capturing linings or lighter insulation, these innovations don’t come cheap.

Safety is another important part of R&D.

Sleeping bags need to be safe, especially in extreme weather. This means extra testing and meeting high safety standards.

All these steps add to the cost.